Piezo microphones are also called contact microphones, this means that they are attached to a surface and can perceive audio vibrations through it. They are not sensitive to air vibrations, but only transduce the sound transmitted by the structure.

They have many applications, they are used to detecting drums hits, to trigger electronic samples or even underwater. For these applications they work fine.

They are often used to amplify acoustic musical instruments, and this is where the problems begin.

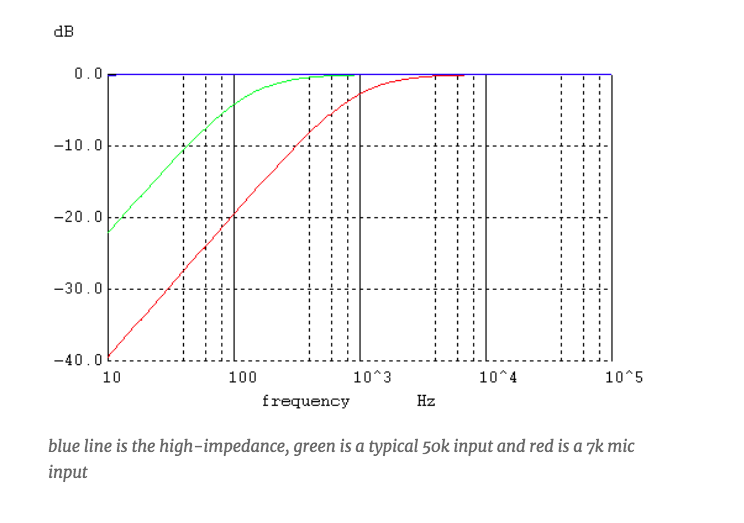

Contact microphones are not well-matched to typical audio inputs. They cannot drive a 50 kilohm input, which is the typical line input.

Most Piezos are tuned speaker elements used in reverse, the microphone is glued to a brass disc designed to resonate between 2-4kHz so that with a small power input you get a great audio output.

The problem is that they are often paired with a standard audio load, which normally loses low frequencies.

The Piezo sensor presents its signal through a series capacitance of approximately 15nF. When connected to a regular 50 kilohm line input, this forms a 200 Hz high pass filter, so here’s the main problem!

And, when connected to a consumer plug-in microphone input with an impedance of about 7 kilohms, the result is a 1kHz high-pass filter.

This should be inserted into a load that is higher than the impedance of the series capacitor at the lowest frequency of interest. If this is 20Hz, since the capacitor impedance is 1 / 2pifreq * C, then it should be above 530k.

This means that a high impedance input gets the blue line in the graph above.

Maybe you might think about EQing it later, but you will also start increasing the noise and hum at low frequencies.

Resources

R. Mudhar – Using Piezo Contact Mics right

Wikipedia – Contact Microphones